Image by rawpixel.com on Freepik

Image by rawpixel.com on Freepik

Written By: Catalyst Partners Staff

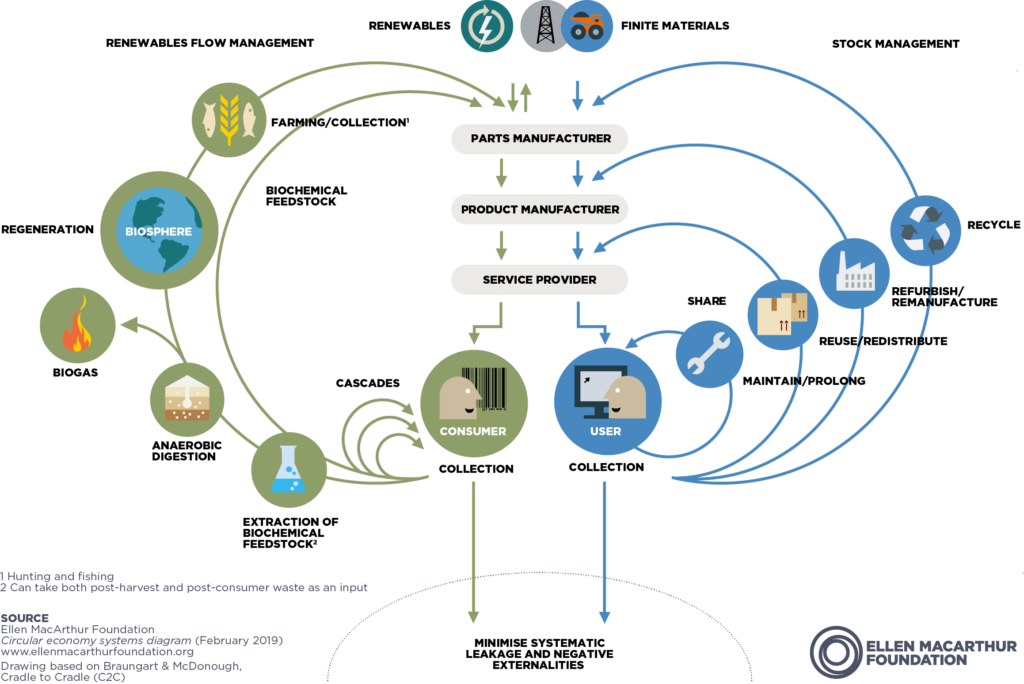

As the global construction industry grapples with the challenges of climate change, there is a growing recognition of the importance of adopting material and resource responsibility practices. According to a report by the United Nations Environment Programme (UNEP), the construction industry uses up to 40% of the world’s total raw materials and (at the same time) is anticipated to generate 2.2 billion tons, per year, by 2025, which is more than twice the weight of all cars that currently exist on the planet. Incorporating material reuse and circular economy principles into new construction projects can help reduce waste, minimize environmental impact, and extend the useful life of materials. In this article, we will explore three effective ways to implement circular economy principles in new construction projects.

Design for Deconstruction/Disassembly

Designing buildings and structures with end-of-life considerations in mind is a fundamental approach to circular economy principles. By designing for deconstruction, it becomes possible to dismantle and recover materials for reuse or repurposing at the end of the building’s useful life. Such a well-designed building can significantly reduce waste, extend the life of materials, and reduce the demand for natural material stock.

Architects and engineers can incorporate existing design features and strategies such as modular construction, demountable partitions, and the use of mechanical fasteners. For instance, modular construction allows us to assemble a structure in prefabricated pieces or modules that can be disassembled and reassembled for another purpose in the future. Demountable partitions refer to flexible wall systems that are assembled using individual panels that can be removed and reused, while mechanical fasteners – such as fasteners instead of adhesives – allow for easy dismantling of a structure without damaging the materials.

In addition, designers can replace materials that are difficult to recycle or dispose of, such as plastics or PVC, with alternatives that can easily be reintroduced into the supply chain. Furthermore, upgrading from basic CAD to Building Information Modeling (BIM) software enables the creation of detailed 3D models and asset records of a building’s components and systems, which can aid in planning for material reuse and identifying opportunities for optimization and waste reduction.

Install Reclaimed and Repurposed Materials

Incorporating circular economy principles in construction projects can be achieved by using recycled and reclaimed materials, resulting in a significant reduction in the environmental impact of new construction projects. In addition, utilizing such materials, which are often less expensive than new materials, can also lead to a reduction in project costs.

The practice of repurposing materials in new and innovative ways is currently being implemented worldwide, showcasing its feasibility and effectiveness. Notably, the HAB Housing development in Bristol, UK, constructed entirely from recycled materials, including timber from shipping containers and car chassis, serves as an exemplary model. This project exemplifies how materials traditionally regarded as waste can be transformed into high-quality building materials.

Another successful example is the Reclaimed Modern House in Santa Barbara, California. This project repurposed salvaged materials from an old barn, such as reclaimed Douglas fir used for the striking exposed wood ceiling, which adds warmth and character to the modern home’s space. Likewise, the Empire Stores development in Brooklyn, New York, transformed an old coffee warehouse into a vibrant mixed-use space, utilizing reclaimed brick and timber from the original building. The project has garnered numerous awards for its sustainable and adaptive reuse of existing materials.

The takeaway? By creatively designing for the repurposing of materials, you and your team can effectively drive circular economy principles immediately, creating sustainable and functional buildings while reducing waste and project costs.

Progress Industry Status Quo via a Circular Procurement Strategy

Procuring materials and products from manufacturers designed for durability, reuse, repair, or recycling is an effective way to incorporate circular economy principles into new construction projects. By procuring materials and products from manufacturers who prioritize these principles, lifecycle costs of buildings can be reduced as products designed for durability and repair require less frequent replacement than those designed for disposal.

Companies can work with suppliers and manufacturers to encourage the development of such products and to develop procurement policies that prioritize their use. They can also require suppliers to provide information about the environmental impact of their products and packaging. Lastly, companies can work with manufacturers to understand the take-back potential of their products and encourage them to join the efforts of leading manufacturers such as Armstrong, CertainTeed, and Owens Corning.

Conclusion

Implementing circular economy principles in construction projects can help reduce waste, minimize environmental impact, and extend the life of materials. By designing for deconstruction, using recycled and reclaimed materials, and implementing a circular procurement strategy, design and construction companies can drive circular economy principles forward. As the world’s population continues to grow, it is essential that the construction industry takes steps to reduce its environmental impact and ensure that resources are used efficiently. Adopting circular economy principles in construction projects is the best step you and your teams can make now to play a role in that increased level of resource efficiency.

How Catalyst Partners can help you incorporate the circular economy into your work:

Materials selection: Our team can assist in selecting materials that are renewable, recycled, or reclaimed, while also recommending materials that can be reused or repurposed at the end of the building’s lifecycle. This includes analyzing the entire life cycle of each material, from extraction to disposal, to ensure that it aligns with circular economy principles.

Learn how to rethink business for a circular economy with Kyle Ritchie’s co-authored book, Circular Economy for Dummies:

Index:

Design for disassembly: Ensure that your building is designed to be taken apart and reused or recycled at the end of their life, ensuring buildings that can be easily disassembled

System design: Explore systems that are energy-efficient and utilize renewable energy sources, including designing buildings that maximize natural light and airflow, and that use energy-efficient lighting and HVAC systems and renewable energy sources

References:

EPA Construction and Demolition Debris: Material Specific Data